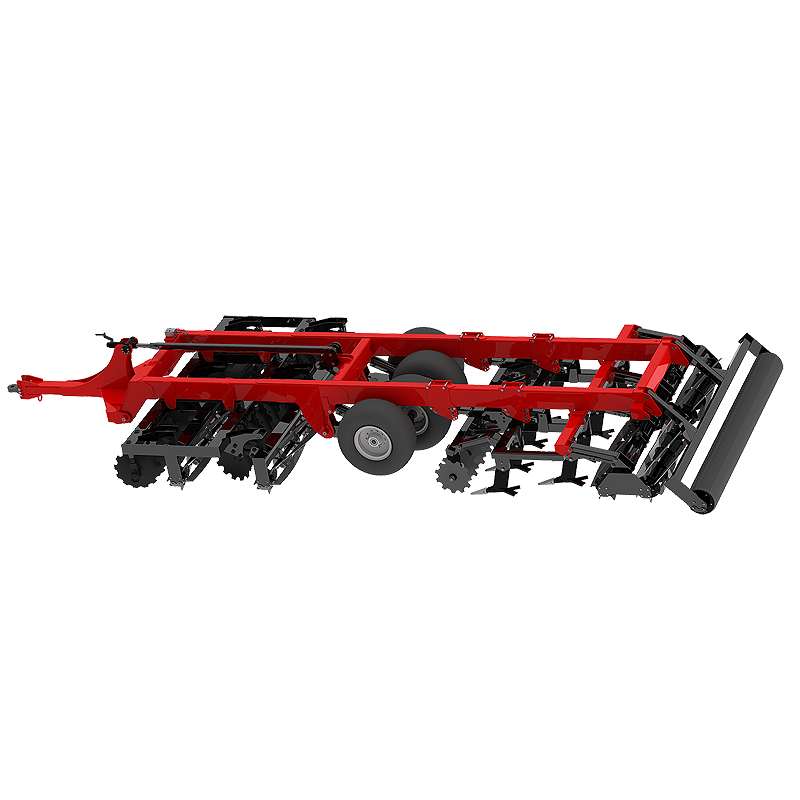

The True One Pass Tillage Solution

Save Time & Reduce Fuel Use

Check out our EPA report on the fuel, time, and emission-reducing benefits of OPTIMIZER here.

The OPTIMIZER is the only one-pass tillage system in the world that offers complete conventional tillage. We designed the OPTIMIZER to lower costs by creating a quality seedbed from the post-harvest state in just one pass.

Save time. Save fuel. Save money.

This machine pays for itself.

The OPTIMIZER is a complete replacement for traditional tillage methods. Combining all necessary implements into one unit leaves a finished field without the soil compaction caused by multiple passes of tractors and implements. Organic residue is mixed into the soil, the traffic pan layer is broken up, and the top soil layer is sealed for a moisture-saving finish. This leaves soil healthier, reduces dust from fine particles, and results in increased yields of up to 10% or more.

Models and sizes available for all your needs.

5.5-ft to 18-ft working widths. Shallow and deep tillage setups available.